High-pressure cold storage air curtain: AFIM IGLO® Technology

Description of the freezer room air curtain for Vanreusel Snacks

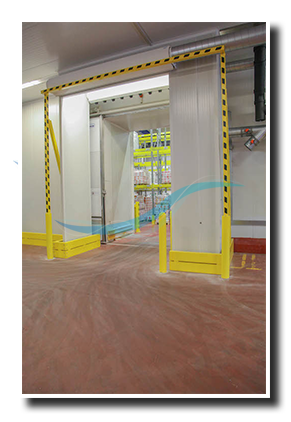

In order to reduce the energy cost of transport to and from its freezer room, Vanreusel Snacks, based in Belgian Hamont, opted in 2013 to install an AFIM IGLO® high-pressure cold storage air curtain in its freezer room. This high-pressure cold storage air curtain was delivered and installed by the company Air In Motion. The combination of the unique functioning of this high-pressure cold storage air curtain (AFIM® Air Doors) with active air drying not only prevents condensation and ice formation, but also considerably reduces energy consumption.

Benefits of the freezer room air curtain for Vanreusel Snacks

The advantage of a high-pressure cold storage air curtain in a freezer room is that it opens up the field of view and thus creates free passage for transport. Due to the high volume of transport going through this entryway, a strip curtain or high-speed door is not a viable solution; this is because it has been found in the past that collision damage is common with these types of doors. Furthermore, the AFIM IGLO® allows for the freezer room temperature to be maintained despite the fact that the door remains open for transport. This strongly reduces the frequency at which the evaporators have to defrost, which not only brings practical benefits but also considerably reduces energy consumption.

About Vanreusel Snacks

This Belgian family company, founded in 1953 by Paul Vanreusel, started out with the preparation of delicatessen products such as ham and various types of pie and sausage. Due to the changing market, the company gradually transitioned to a focus on deep-frozen snacks in 1970. Indeed, the product range was expanded to include modern-day “classics” such as cervelats, frikandels, hamburgers and meatballs. In 1976, Paul’s sons took over and fully dedicated themselves to making quality snacks for the hospitality industry.

Today, the company offers a highly varied selection of such deep-frozen snacks, and Vanreusel Snacks has grown into a leading snack manufacturer. Moreover, the 3rd-generation Vanreusels, Paul-Emmanuel and Roel, are now at the helm together with Theo Vanreusel. Lukas Vanreusel has also started a production facility in Hungary under the name Flema. This factory currently produces only satays and other skewered products.

Vanreusel Snacks responds to today’s trends without ever losing sight of its client’s needs, because once you’ve tried a Vanreusel Snack, you can never go back!

Source: https://www.vanreusel.be

Sector

Food production and distribution

Location

Hamont (Belgium)

Benefits

– Free passage for transport

– Freezer temperature maintained

– Evaporators need to defrost less

– Saves energy

Temperatures

– Adjacent room: +12°C

– Freezer room: -22°C

Solution provided by

AFIM IGLO® (cold storage air curtain)